-

Products

-

Bathrive-V6 furnace temperature tester

-

Bathrive-SU furnace temperature tester

-

Bathrive-FBT furnace temperature tester

-

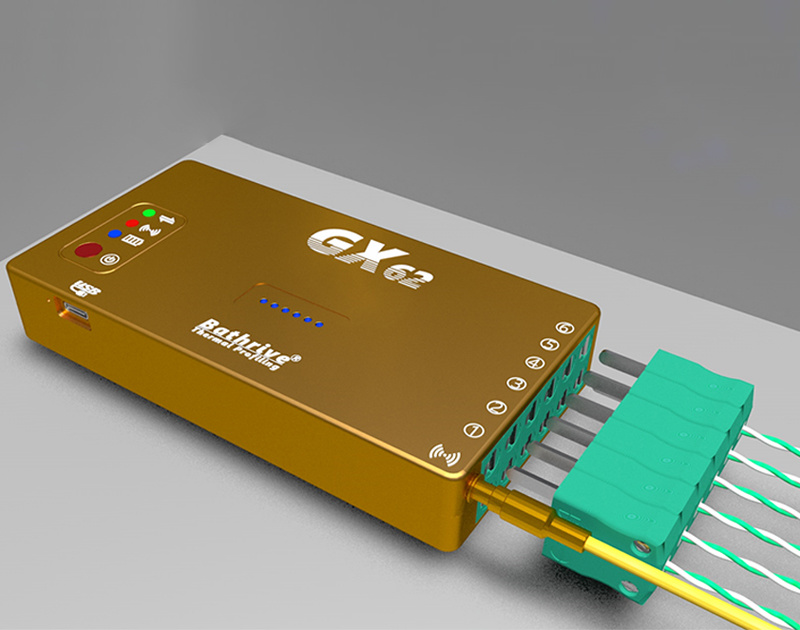

Bathrive-GX wireless furnace temperature tester

-

Bathrive-TMS online furnace temperature monitoring system

-

Slim Series Wireless Furnace Temperature Tester

-

2D solder paste thickness gauge

-

3D solder paste thickness gauge

-

High temperature insulation box

-

Auxiliary temperature measurement device

-

Oxygen concentration analyzer

-

- Home

-

Products

» Bathrive-V6 furnace temperature tester » Bathrive-SU furnace temperature tester » Bathrive-FBT furnace temperature tester » Bathrive-GX wireless furnace temperature tester » Bathrive-TMS online furnace temperature monitoring system » Slim Series Wireless Furnace Temperature Tester » 2D solder paste thickness gauge » 3D solder paste thickness gauge » High temperature insulation box » Auxiliary temperature measurement device » Oxygen concentration analyzer

- About Us

- News

- Case Video

- Cooperative partner

- Contact us

-

English

English

Maintenance of Furnace Temperature Tester

Release time: 2025-11-10

Maintenance of Furnace Temperature Tester

The core maintenance principle of the furnace temperature tester is "regular cleaning, calibration of core components, and standardized storage and use", which can significantly extend its service life and ensure data accuracy.

1. Daily Usage Maintenance

- Check the sensor (thermocouple) before each use to ensure the probe is free of bending or damage, and the terminal blocks are not loose or oxidized.

- Clean dust and oil from the tester host and sensor surface immediately after testing. Use a dry soft cloth for wiping; do not use water or corrosive cleaners.

- Avoid severe impact or dropping of the tester, and prevent excessive pulling or squeezing of the sensor cable.

- Use the original charger for charging. Recharge when the power is below 20% to avoid storing with insufficient power.

2. Key Regular Maintenance Items

- Sensor Calibration: Calibrate the thermocouple every 6-12 months. Send it to a professional institution or use a standard temperature field for comparison to ensure the temperature measurement error is within the allowable range.

- Battery Maintenance: If not in use for a long time, recharge it every 3 months (keep 50%-80% power) to avoid battery aging and damage.

- Interface Inspection: Regularly clean dust from data interfaces (USB, Bluetooth, etc.). Wipe with a cotton swab dipped in a small amount of anhydrous alcohol to prevent poor contact.

- Software Update: Timely update the supporting software of the tester to fix bugs and optimize the stability of data collection.

3. Storage and Environmental Requirements

- Store in a dry and well-ventilated environment with a temperature of -10℃~40℃ and humidity not exceeding 85% to prevent internal components from dampness.

- Keep away from strong magnetic fields, strong electric fields, and corrosive gases (such as acid-base vapor) to avoid interfering with the sensor and host circuit.

- Store the sensor separately, which can be wound into a loose coil to avoid permanent damage to the cable creases.

4. Common Fault Prevention

- Do not use it in an over-range temperature environment to prevent sensor burnout or host overheating.

- When data collection is abnormal, first check if the sensor connection is firm, then check if calibration is needed, instead of directly disassembling the host.

- If the tester gets wet or contaminated with oil, cut off the power immediately, absorb moisture with a dry soft cloth, and send it for repair if necessary. Do not turn it on by yourself.

Contact:Mr. Xu

Mobile phone:13714620954

Fax:0755-27326409

Tel: +86-4008893896

Email: bathrive@163.com

Add:207, Floor 2, No. 22-1, Fengtang Avenue, Xintian Community, Fuhai Street, Bao'an District, Shenzhen

Quick Navigation

Online Message

Copyright 2009-20122 Shenzhen Jingkechuang Electronic Equipment Co., Ltd All Rights Reserved 粤ICP备17088750号