-

Products

-

Bathrive-V6 furnace temperature tester

-

Bathrive-SU furnace temperature tester

-

Bathrive-FBT furnace temperature tester

-

Bathrive-GX wireless furnace temperature tester

-

Bathrive-TMS online furnace temperature monitoring system

-

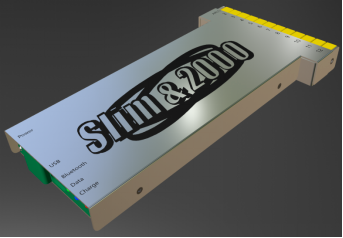

Slim Series Wireless Furnace Temperature Tester

-

2D solder paste thickness gauge

-

3D solder paste thickness gauge

-

High temperature insulation box

-

Auxiliary temperature measurement device

-

Oxygen concentration analyzer

-

- Home

-

Products

» Bathrive-V6 furnace temperature tester » Bathrive-SU furnace temperature tester » Bathrive-FBT furnace temperature tester » Bathrive-GX wireless furnace temperature tester » Bathrive-TMS online furnace temperature monitoring system » Slim Series Wireless Furnace Temperature Tester » 2D solder paste thickness gauge » 3D solder paste thickness gauge » High temperature insulation box » Auxiliary temperature measurement device » Oxygen concentration analyzer

- About Us

- News

- Case Video

- Cooperative partner

- Contact us

-

English

English

Causes of temperature deviation in oven temperature testing.

Release time: 2025-11-17

Equipment-related issues

- Sensor aging or damage: Core components like thermocouples and thermal resistors experience performance degradation over time.

- Internal circuit faults: Malfunctions in amplification circuits or AD conversion modules affect signal processing accuracy.

- Insufficient device precision: The instrument’s accuracy grade fails to meet high-demand temperature testing scenarios.

Improper testing operations

- Damaged or poorly shielded test cables: External interference distorts measurement signals.

Environmental and operational influences

- Excessive ambient temperature fluctuations: Operating conditions exceed the instrument’s specified range.

- Uneven airflow or radiation in the furnace: Causes local temperature variations.

- Unstable power supply: Affects the performance of internal electronic components.

Lack of calibration and maintenance

- Infrequent calibration: Measurement benchmarks drift over time without periodic adjustments.

- Contamination on sensors or enclosures: Oil, dust, or debris impairs heat conduction and signal transmission.

Neglect of regular maintenance: Internal component dust accumulation or moisture leads to performance degradation.

Contact:Mr. Xu

Mobile phone:13714620954

Fax:0755-27326409

Tel: +86-4008893896

Email: bathrive@163.com

Add:207, Floor 2, No. 22-1, Fengtang Avenue, Xintian Community, Fuhai Street, Bao'an District, Shenzhen

Quick Navigation

Online Message

Copyright 2009-20122 Shenzhen Jingkechuang Electronic Equipment Co., Ltd All Rights Reserved 粤ICP备17088750号